| Material |

| Made from various grades of stainless steel, commonly SS304 and SS316, providing excellent resistance to corrosion and a wide range of chemicals. |

| SS316 offers superior resistance to chloride-induced corrosion compared to SS304. |

| Size and Capacity |

| Available in standard sizes to accommodate industry-standard bag filters, such as #1 (7” x 16”) and #2 (7” x 32”). |

| Can be configured to hold single or multiple filter bags, depending on application needs. |

| Connections |

| Inlet and outlet connections are available in various types, such as NPT, BSP, or flanged connections |

| Connection sizes typically range from 1 inch to several inches, based on the required flow rate |

| Pressure Rating |

| Typically rated for pressures up to 300 psi or higher, depending on the design and construction. |

| Temperature Range |

| Suitable for high-temperature applications, often up to 400°F (204°C), depending on the gasket and seal material used. |

| Finish |

| Available with various surface finishes, such as electro-polished, sandblasted, or passivated, to suit specific aesthetic and hygienic requirements. |

Bag Filter Housing

Bag Filter Housing

Stainless steel (SS) bag filter housings are widely used in industrial applications requiring robust and durable filtration solutions. Known for their strength, corrosion resistance, and ability to withstand high temperatures and pressures, these housings are ideal for demanding environments. Here’s an in-depth look at SS bag filter housings:

- Single Bag filter Specifications

- Single Bag filter Benefits

- Single Bag filter Applications

- Single Bag filter Installation and Maintenance

- Single Bag filter Considerations

- Multiple Bag filter Specifications

- Multiple Bag filter Benefits

- Multiple Bag filter Installation and Maintenance

- Multiple Bag filter Considerations

| Durability |

| Offers exceptional strength and longevity, even in harsh environments. |

| Corrosion Resistance |

| Resists rust and corrosion, making it suitable for use with a wide range of chemicals and aggressive media. |

| High Temperature and Pressure Tolerance |

| Capable of handling high-pressure and high-temperature applications. |

| Sanitary Options |

| Available with sanitary fittings and designs, making them suitable for applications in the food, beverage, and pharmaceutical industries. |

| Petrochemicals |

| Applicable in water flooding, completion fluids, and amines within the petrochemical industry. |

| Chemical Processing |

| Used in the filtration of aggressive chemicals and solvents. |

| Food and Beverage |

| Ideal for use in breweries, wineries, and food processing plants due to their sanitary properties. |

| Oil and Gas |

| Suitable for filtration of fuels, lubricants, and hydraulic fluids. |

| Water Treatment |

| Used in potable and wastewater treatment systems. |

| Pharmaceuticals |

| Employed in the filtration of process liquids and ingredients. |

| Installation |

| Requires proper support and alignment to avoid stress on connections. Ensure compatibility with process fluids and operating conditions. |

| Maintenance |

| Regular monitoring and replacement of filter bags are essential for maintaining filtration efficiency and avoiding blockages. |

| Cost |

| Stainless steel housings are more expensive than PVC or other plastic options, but their durability and performance often justify the cost in demanding applications. |

| Weight |

| Heavier than plastic housings, which may require additional support and handling considerations during installation. |

| Surface Finish |

| Choose the appropriate surface finish for specific applications, especially in sanitary or aesthetic-sensitive environments. |

| Considerations |

| Stainless steel bag filter housings offer a reliable and robust solution for industrial filtration needs, providing superior performance in terms of durability, chemical resistance, and temperature and pressure handling capabilities. They are a preferred choice in industries where high standards of hygiene, corrosion resistance, and mechanical strength are required. |

| Considerations |

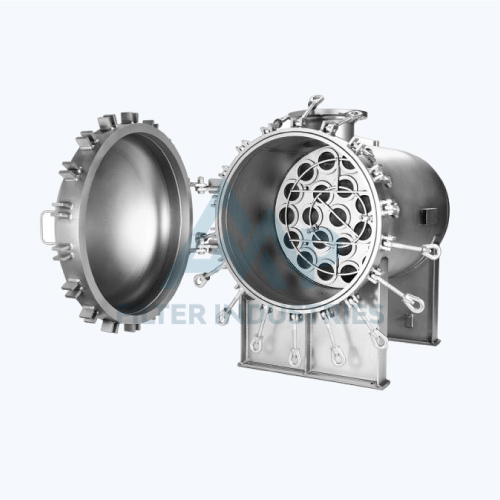

| Multiple bag filter housings are designed to accommodate multiple filter bags within a single housing unit. This setup is ideal for high-flow applications and processes that require significant filtration capacity. Here’s a comprehensive overview of multiple bag filter housings, including their features, benefits, and applications: |

| \Material |

| Typically constructed from stainless steel (SS304 or SS316) for superior corrosion resistance and durability. |

| Other materials like carbon steel or polypropylene may be used for specific applications requiring lower cost or different chemical compatibilities. |

| Capacity |

| Designed to hold multiple filter bags, commonly ranging from 2 to 24 or more bags per housing, depending on the required flow rate and filtration area. |

| Accommodates standard bag sizes, such as #1 (7” x 16”) and #2 (7” x 32”). |

| Connections |

| Inlet and outlet connections are available in various configurations, such as NPT, BSP, flanged, or sanitary fittings. |

| Connection sizes typically range from 2 inches to 24 inches or more, based on the required flow rate. |

| Pressure Rating |

| Typically rated for pressures up to 150 psi or higher, depending on the design and construction. |

| Temperature Range |

| Suitable for a wide range of temperatures, often up to 400°F (204°C) with appropriate gasket and seal materials. |

| Design Features |

| Swing bolt or quick-opening lid for easy access and maintenance. |

| Vent and drain ports for easy air release and draining of liquid. |

| Differential pressure gauges or indicators to monitor filter condition and efficiency. |

| High Flow Capacity |

| Suitable for applications requiring large volumes of liquid to be filtered quickly and efficiently. |

| Extended Service Life |

| Multiple bags allow for longer operation times between maintenance and bag changes. |

| Versatility |

| Can be used with a variety of filter bags to target different contaminants and achieve desired filtration levels. |

| Efficiency |

| Reduces downtime with quick bag change-outs and easy maintenance access. Applications |

| Water Treatment |

| Used in large-scale municipal and industrial water treatment systems for removing suspended solids. |

| Chemical Processing |

| Filters large volumes of aggressive chemicals, acids, and solvents in industrial processes. |

| Food and Beverage |

| Suitable for high-volume filtration in breweries, dairies, and food processing plants. |

| Oil and Gas |

| Utilized in the filtration of fuels, lubricants, and other hydrocarbons in refining and production operations. |

| Pharmaceuticals |

| Employed in high-flow filtration of process fluids and ingredients, ensuring purity and compliance with industry standards. |

| Installation |

| Requires adequate support and alignment to prevent stress on connections. Ensure compatibility with process fluids and conditions. |

| Maintenance |

| Regular monitoring of differential pressure and routine replacement of filter bags are crucial to maintaining efficiency and preventing system blockages. |

| Cost |

| The initial investment for multiple bag filter housings is higher than for single-bag systems, but the benefits in efficiency and capacity often outweigh the cost. |

| Footprint |

| Requires sufficient space for installation and access for maintenance, including space for bag change-out. |

| Flow Dynamics |

| Proper design and selection are essential to ensure even flow distribution across all bags to maximize filtration efficiency and bag life. |

| Considerations |

| Multiple bag filter housings offer an efficient solution for high-flow and high-capacity filtration needs. They are a critical component in industries where large volumes of liquid must be processed quickly and reliably, providing both operational efficiency and adaptability to various filtration challenges. |