| Material and Construction |

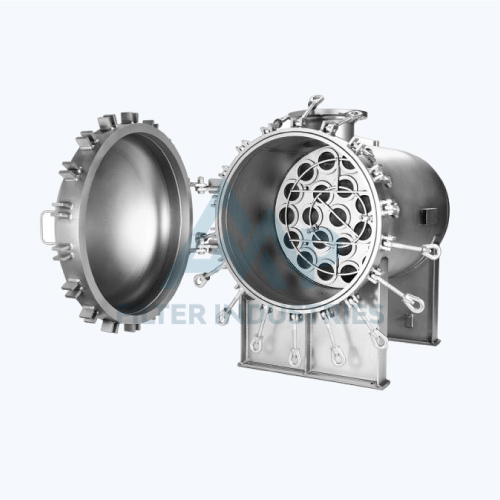

| Materials: Typically made from high-grade stainless steel (e.g., SS304, SS316L) to ensure durability, resistance to corrosion, and easy cleaning. |

| Design: Smooth, polished surfaces (often to a high mirror finish) to minimize contamination risks and facilitate easy cleaning. |

| Sanitary Design |

| Seals and Gaskets: Equipped with hygienic seals and gaskets made from materials like EPDM, silicon, or Viton to prevent leaks and ensure compatibility with sterilization processes. |

| Connections: Hygienic connections such as sanitary clamps, Tri-Clamp, or butt-weld fittings to ensure easy assembly and disassembly while maintaining a clean environment. |

| Easy Cleaning and Sterilization |

| CIP/SIP Capability: Designed to be cleaned in place (CIP) and sterilized in place (SIP), reducing the need for disassembly and minimizing contamination risks. |

| Drainage: Features proper drainage systems to ensure all cleaning agents and contaminants are fully removed. |

| Filtration and Performance: |

| Cartridge Options: Compatible with various filter cartridges, including pleated, wound, and membrane types, depending on the application needs. |

| Pressure Ratings: Built to handle the specific pressure requirements of the application, ensuring reliable performance under operational conditions. |

| Visual Inspection |

| Transparency: Some housings come with sight glasses or windows to allow visual inspection of the filter and fluid flow, ensuring system transparency and ease of monitoring. |

Hygienic Filter Housing

Hygienic Filter Housing

Hygienic filter housings are specifically designed for applications requiring high standards of cleanliness and contamination control. They are commonly used in industries such as food and beverage, pharmaceuticals, and biotechnology, where maintaining hygienic conditions is critical. Here’s an overview of hygienic filter housings, including their features, benefits, and applications

| Hygiene and Safety |

| Contamination Control: Designed to meet stringent hygiene standards, reducing the risk of contamination in sensitive processes. |

| Regulatory Compliance: Meets industry standards and regulations for cleanliness and safety, crucial in sectors like food and beverage and pharmaceuticals. |

| Operational Efficiency |

| Easy Maintenance: Facilitates quick and effective maintenance, cleaning, and cartridge replacement. |

| Reduced Downtime: CIP/SIP capability reduces downtime associated with manual cleaning and system disassembly. |

| Versatility |

| Wide Range of Applications: Suitable for various applications including liquid filtration, air filtration, and gas filtration in sanitary environments. |

| Food and Beverage |

| Use: Ensures the purity and safety of food products and beverages by preventing contamination during processing. |

| Pharmaceuticals |

| Use: Maintains the integrity of pharmaceutical products by filtering out contaminants during manufacturing and processing. |

| Biotechnology: |

| Use: Critical for maintaining aseptic conditions in biotechnological processes, including cell culture and bioprocessing. |

| Cosmetics |

| Use: Ensures the cleanliness of cosmetic products and prevents contamination during production. |

| Chemical Processing |

| Use: Used in the processing of chemicals where hygiene is a critical factor. |

| Regular Cleaning |

| Follow manufacturer guidelines for cleaning and sterilization to ensure optimal performance and compliance with hygiene standards. |

| Cartridge Replacement |

| Replace filter cartridges based on the manufacturer’s recommendations or when performance indicators signal a need for change. |

| Inspection |

| Regularly inspect for signs of wear, leaks, or contamination, and perform necessary maintenance to maintain hygienic conditions. |

| Hygienic filter housings are essential in maintaining high standards of cleanliness and contamination control in various industries. Their design and construction ensure that they meet the rigorous demands of sanitary applications while providing reliable and efficient filtration. |

| Seawater Desalination |

| Robust against corrosion, making it ideal for harsh seawater environments. |

| Applications |

| Food |

| Dairy |

| Beverage |

| Electronics and Pharmaceutical Industries |