| Collection |

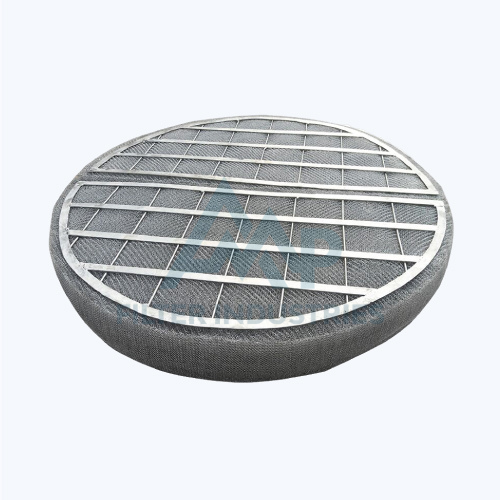

| The filter media (such as a mesh screen, drum, or cartridge) captures contaminants from the fluid as it passes through. |

| Coalescence: |

| The filter media encourages the smaller droplets to merge or coalesce into larger droplets. This is typically facilitated by the filter's fine fibers or media, which provide a surface for the droplets to contact and merge. |

| Separation |

| Once the droplets have coalesced into larger sizes, they separate from the fluid stream due to gravity or centrifugal forces. In liquid-liquid separation, the larger droplets settle out of the stream due to density differences. |

| Discharge |

| The separated impurities or droplets are collected and removed, while the clean fluid exits the coalescer. |

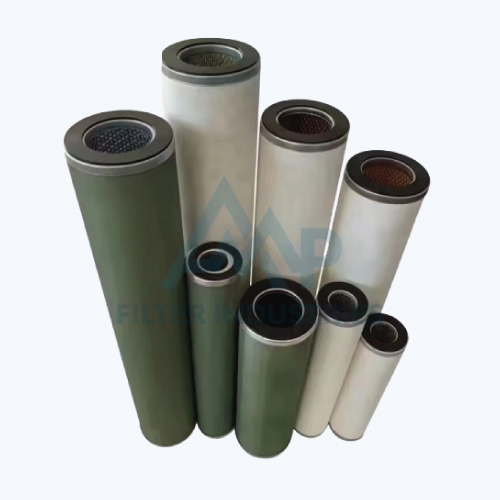

Coalescer

Coalescer

A coalescer filter is a specialized filtration device used to separate immiscible liquids or to remove contaminants from a liquid or gas stream. Coalescers are commonly used in applications where the removal of fine droplets or particulate matter is essential for the purity and efficiency of the process. Here’s a detailed look at coalescer filters, their operation, types, and applications:

How Coalescer Filters Work

Coalescer filters operate on the principle of coalescence, where small droplets of liquid are combined into larger droplets, making it easier to separate them from the fluid stream. This is achieved through a multi-stage process:

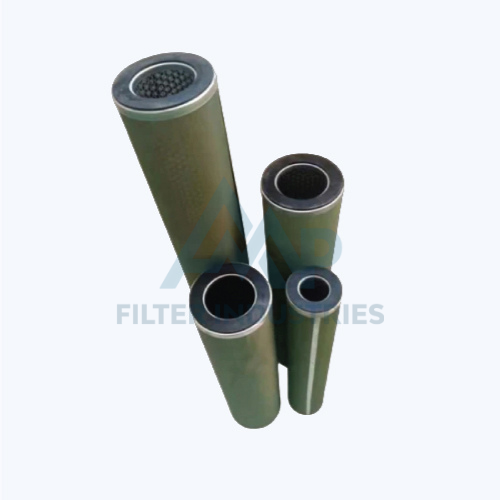

| Liquid-Liquid Coalescers |

| Purpose: Separate two immiscible liquids, such as oil and water. |

| Applications: Used in oil refineries, chemical plants, and other industrial processes where oil-water separation is required. |

| Liquid-Gas Coalescers |

| Purpose: Remove liquid droplets from gas streams. |

| Applications: Used in natural gas processing, air compressor systems, and other gas purification processes. |

| Particulate Coalescers |

| Purpose: Remove solid particles from liquids or gases. |

| Applications: Often used in combination with liquid or gas coalescers to ensure complete purification. |

| High Efficiency |

| Effective in removing fine droplets and particulates, resulting in high purity of the processed fluid. |

| Versatile Applications |

| Suitable for various industrial sectors, including oil and gas, petrochemicals, pharmaceuticals, and food processing. |

| Low Maintenance |

| Designed for easy replacement and maintenance, reducing downtime. |

| Cost-Effective: |

| Improves process efficiency and reduces the need for additional separation equipment. |

| Oil and Gas Industry |

| Separation of oil from produced water, removal of water from fuels and lubricants. |

| Chemical Processing |

| Separation of solvents and chemical mixtures, ensuring purity and quality of products. |

| Water Treatment |

| Removal of oil and other contaminants from wastewater, ensuring compliance with environmental regulations. |

| Aviation and Automotive |

| Purification of fuels and lubricants to ensure efficient engine performance and longevity. |

| When selecting a coalescer filter, several factors should be considered: |

| Fluid Properties: The type and properties of the fluid to be processed, including viscosity, density, and chemical compatibility. |

| Flow Rate: The required flow rate and pressure drop across the filter. |

| Operating Conditions: Temperature and pressure conditions of the application. |

| Material Compatibility: The construction materials of the coalescer must be compatible with the process fluids to prevent corrosion or degradation. |

| Conclusion |

| Coalescer filters are essential components in many industrial processes, offering effective separation and purification of fluids. Their ability to efficiently remove fine droplets and particles makes them invaluable in maintaining the quality and efficiency of various systems. By understanding the specific requirements of the application, the right coalescer filter can be selected to achieve optimal performance and reliability. |