| How Demister Pads Work |

| Demister pads work based on the principle of inertial impaction and coalescence: |

| Inertial Impaction |

| As the gas stream passes through the demister pad, the inertia of the liquid droplets causes them to deviate from the gas flow path and collide with the wire or mesh surface. |

| Coalescence |

| The captured droplets on the surface coalesce to form larger droplets, which eventually become heavy enough to drain back into the liquid phase, typically collected at the bottom of the vessel. |

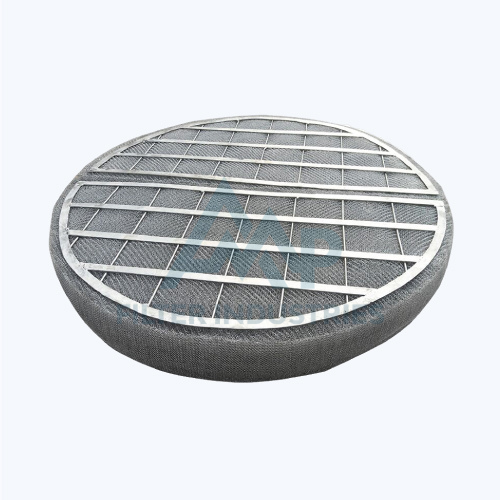

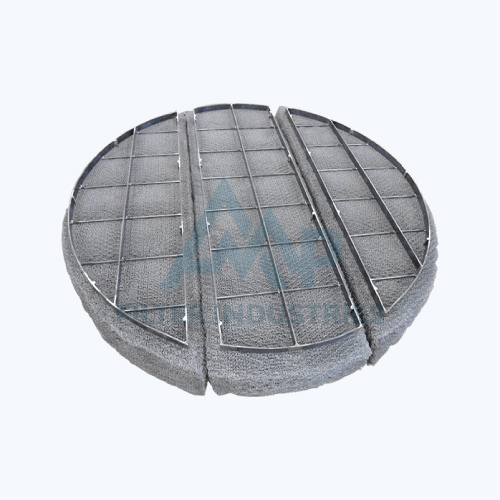

Demister Pad

Demister Pad

A demister pad is an essential component used in various industrial processes to remove liquid droplets from gas streams. These devices are crucial for ensuring the purity of gases and preventing liquid carryover, which can cause operational issues or contamination in subsequent processes. Here’s a detailed look at demister pads, including their function, types, and applications:

What is a Demister Pad?

A demister pad, also known as a mist eliminator, is a porous pad typically made of knitted or woven wire mesh or other materials like plastic or fiberglass. Its primary function is to separate liquid droplets from gas streams, ensuring that the exiting gas is free from entrained liquids.

- How Demister Pads Work

- Types of Demister Pads

- Applications of Demister Pads

- Benefits of Using Demister Pads

- Selecting the Right Demister Pad

| Wire Mesh Demisters |

| These are the most common type, made from woven or knitted wire mesh, usually stainless steel, to provide durability and resistance to corrosion. |

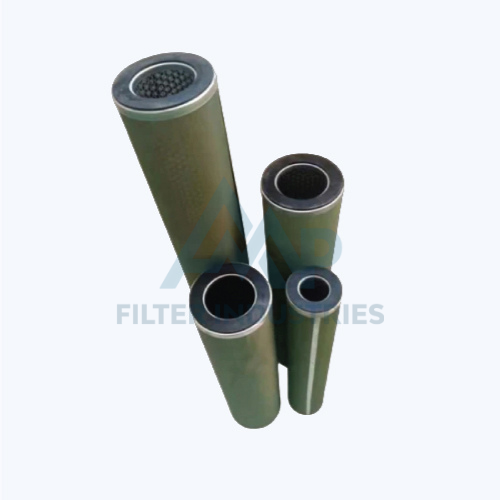

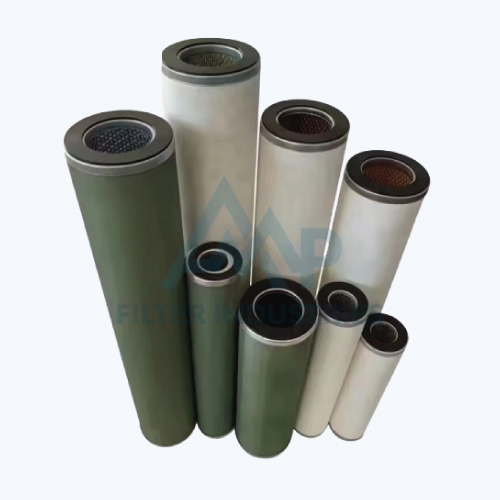

| Fiber Bed Demisters |

| Made from fine fibers, these are used for applications requiring high efficiency and the removal of very fine droplets. |

| Vane Type Demisters |

| These use a series of corrugated plates or vanes to create a zigzag path for the gas flow, effectively removing droplets through inertial impaction. |

| Chemical Processing |

| Used in distillation columns, absorbers, and scrubbers to remove entrained liquids from gas streams. |

| Oil and Gas |

| Employed in gas scrubbers and separators to prevent liquid carryover. |

| Power Generation |

| Used in cooling towers and exhaust systems to minimize liquid entrainment. |

| Food and Beverage |

| Utilized in processes like fermentation to ensure product purity. |

| Pharmaceuticals |

| Essential in maintaining purity levels by preventing cross-contamination of liquids and gases. |

| Improved Process Efficiency |

| By ensuring the purity of gas streams, demister pads help maintain process efficiency and product quality. |

| Reduced Maintenance Costs |

| Preventing liquid carryover reduces corrosion and wear in downstream equipment, lowering maintenance costs. |

| Environmental Compliance |

| Effective separation of liquid droplets helps industries comply with environmental regulations by minimizing emissions. |

| Selecting the Right Demister Pad |

| When selecting a demister pad, consider the following factors: |

| Material Compatibility |

| Choose materials that are resistant to the chemicals and temperatures in the process. |

| Droplet Size |

| Ensure the demister can efficiently remove the smallest droplet size present in the gas stream. |

| Pressure Drop |

| Opt for a design that minimizes pressure drop while maximizing separation efficiency. |

| Selecting the Right Demister Pad |

| By choosing the appropriate type of demister pad for your specific application, you can enhance process performance, ensure equipment longevity, and achieve regulatory compliance. Let me know if there's anything specific you want to know about demister pads! |