| Separation of Phases |

| Liquid-Liquid Separation: Separates immiscible liquids (e.g., oil from water) by exploiting differences in their densities or other properties. |

| Gas-Liquid Separation: Removes liquid droplets from gases (e.g., removing water vapor from compressed air). |

| Particle Removal |

| Solid-Liquid Separation: Removes solid particles suspended in liquids (e.g., dirt or rust in water). |

| Solid-Gas Separation: Filters out solid particles from gases (e.g., dust in air). |

| Key Features |

| Contaminant Removal: Protects sensitive equipment and processes by removing contaminants that could cause damage or reduce efficiency. |

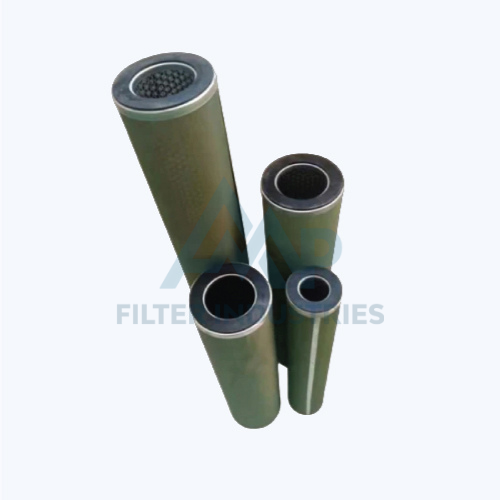

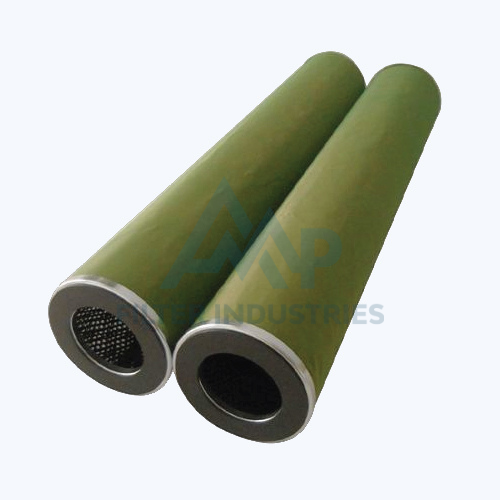

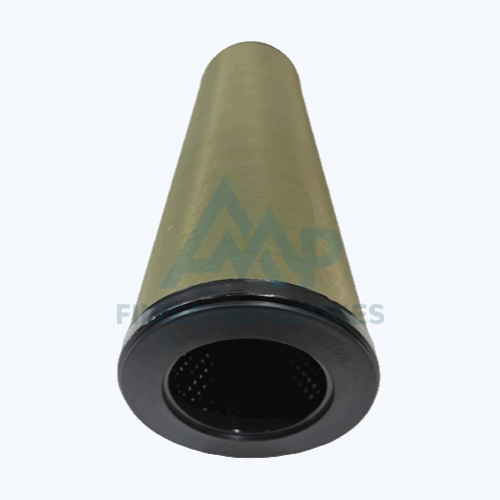

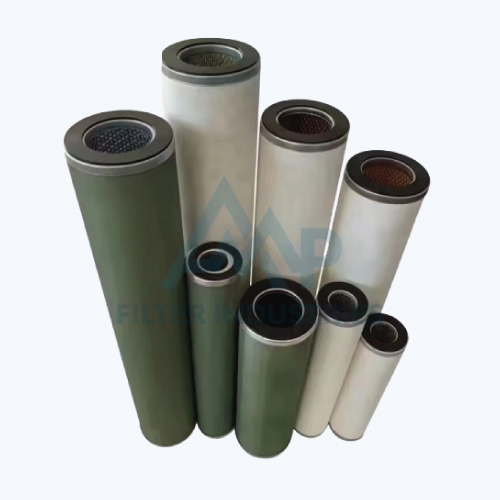

Seperator

Seperator

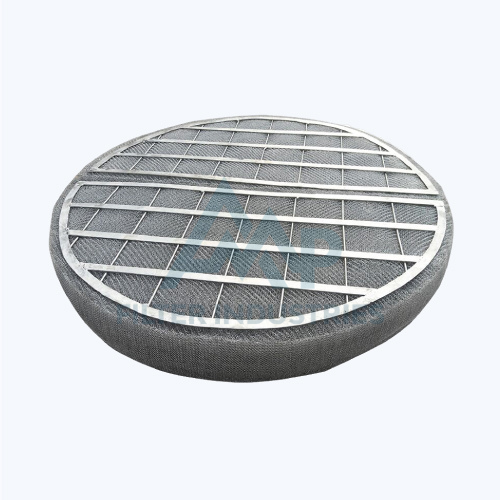

A separator filter is a type of filtration device designed to separate contaminants or particles from a fluid (liquid or gas) stream. These filters are used to improve the purity of the fluid and protect downstream equipment from damage or fouling. Separator filters are commonly employed in various industrial, commercial, and automotive applications.

| Centrifugal Separators |

| Mechanism: Uses centrifugal force to separate particles or phases based on their density. |

| Applications: Commonly used for oil-water separation and in diesel engines. |

| Cyclone Separators |

| Mechanism: Utilizes a cyclone chamber where centrifugal forces separate particles from the gas stream. |

| Applications: Used for dust collection and separating large particulates from air. |

| Coalescing Filters |

| Mechanism: Uses filter media to coalesce small droplets of liquid into larger droplets, which can then be separated from the main fluid stream. |

| Applications: Effective in removing water from fuels and lubricants. |

| Bag and Cartridge Filters |

| Mechanism: Employs filter bags or cartridges to trap particles from liquids. |

| Applications: Used for filtration in various industrial processes, including chemical and water treatment. |

| Hydrocyclones |

| Mechanism: Similar to cyclone separators, but specifically designed for liquid-solid separation. |

| Applications: Commonly used in mining and mineral processing. |

| Membrane Separators |

| Mechanism: Uses membrane technology to separate particles or phases based on size exclusion or chemical affinity. |

| Applications: Used in water purification, pharmaceuticals, and food processing. |

| Automotive Industry |

| Fuel Filters: Remove impurities from fuel to protect engine components. |

| Oil Filters: Separate contaminants from engine oil. |

| Industrial Processes |

| Chemical Processing: Removes solid particles or phases from chemical streams. |

| Oil and Gas: Separates oil, water, and gas in extraction and refining processes |

| Water Treatment |

| Municipal Water: Removes suspended solids and other contaminants from potable water. |

| Wastewater Treatment: Separates solids from wastewater. |

| HVAC Systems |

| Air Filtration: Removes dust, pollen, and other particulates from air streams. |

| Food and Beverage |

| Clarification: Separates solids from liquids in production processes. |

| Magnetic Filters |

| Design: Incorporate magnets to capture metal particles in addition to traditional filtration media. |

| Improved Equipment Longevity |

| Protects machinery and components from wear and damage caused by contaminants. |

| Enhanced Process Efficiency |

| Ensures that processes run smoothly and effectively by removing unwanted particles or phases. |

| Regulatory Compliance |

| Helps meet industry standards and regulations for fluid purity and quality. |

| Heavy Equipment |

| Use: Used in construction and agricultural equipment to maintain the performance and longevity of engines and hydraulic systems. |

| Reduced Maintenance Costs |

| Minimizes the need for frequent cleaning and repairs by preventing the accumulation of contaminants. |

| Benefits of Separator Filters |

| Separator filters play a crucial role in various applications by ensuring that fluids are free of unwanted contaminants, improving the efficiency and longevity of equipment, and meeting industry standards. |