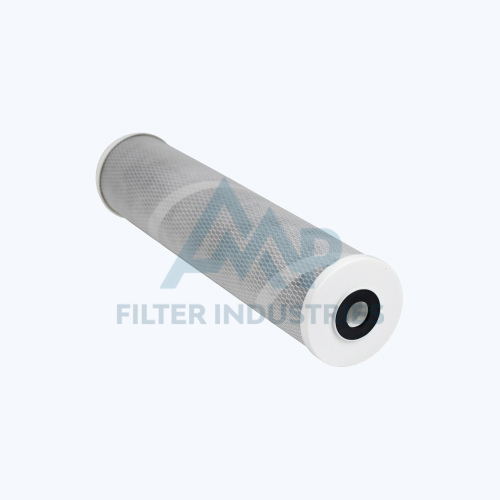

| Extruded Carbon Block Filter Cartridges |

| Composition: Made from coconut shell or coal-based activated carbon combined with an inorganic liquid binder. |

| Manufacturing Process: The mixture is poured into a mold, compressed under high pressure, and dried. |

| Functions: Absorbs odor, residual chlorine, and pigments. |

| Applications: Commonly used in the food and beverage industry, drinking water purification, and alcohol production. |

| Sintered Carbon Block Cartridges |

| Composition: Mixture of activated carbon powder and polymer hot-melt pore-forming material. |

| Manufacturing Process: The mixture is molded and sintered at temperatures of 200-300℃. |

| Characteristics: Maintains the large specific surface area of activated carbon due to open micropores formed during sintering. |

| Functions: Offers improved filtration efficiency compared to extruded carbon blocks. |

| Applications: Used in drinking water systems, hospital water treatment, food and beverage processing, and production of pure water. |

| Granular Activated Carbon Filters |

| Composition: Contains coconut shell or coal-based activated carbon granules. |

| Manufacturing Process: The granules are encased in a plastic filter shell using ultrasonic heat welding without chemical additives. |

| Functions: Removes organic pollutants, chemical pesticides, residual chlorine, pigments, and odors from water. |

| Applications: Suitable for drinking water, commercial water, and domestic water filtration systems. |

| Carbon Impregnated Cellulose Filters |

| Composition: Made of a fiber filter membrane wrapped with activated carbon fiber cloth. |

| Functions: Traps pollutants while absorbing odors and organic pigments. |

| Applications: Used in printed circuit boards, surface treatment, electroplating solutions, and coatings. |

Carbon Cartridges

Carbon Cartridges

Activated carbon filter cartridges are essential components in various filtration systems, leveraging the unique properties of activated carbon to remove contaminants and impurities from liquids. Here’s an overview of different types of activated carbon filter cartridges, their performance characteristics, and application areas

| High Flow Rate |

| Ensures efficient filtration without significant pressure drops. |

| High Dirt Holding Capacity |

| Allows for longer service life and reduced maintenance frequency. |

| Chlorine Removal Efficiency |

| Effectively removes chlorine and its by-products, improving water taste and safety. |

| Sizes Available |

| 10", 20", 30", 40" lengths. |

| Filtration Rating |

| Available in 5 or 10-micron ratings. |

| Dimensions |

| Outside Diameter: 63 mm or 116 mm |

| Inside Diameter: 28 mm |

| Water Treatment |

| Essential in residential, commercial, and industrial water purification systems. |

| Membrane Pre-filter |

| Used as a pre-filtration stage to protect and extend the life of membrane filters. |

| Edible and Mineral Oil Filtration |

| Removes impurities and enhances product quality. |

| Bottled Water and Flavors |

| Ensures the removal of contaminants for better taste and safety. |

| Polishing Lines |

| Used in the final filtration stage to ensure clarity and purity of liquids. |

| Applications |

| Activated carbon filter cartridges are versatile and highly effective in removing a wide range of impurities, making them invaluable in various industries and applications. |