| Particle Removal |

| The filter captures solid particles such as dust, dirt, and rust. This is often achieved using a pleated or woven filter media that acts as a barrier. |

| Moisture Removal |

| Filters designed to remove moisture typically include a coalescing element that combines water droplets into larger ones, which then settle out of the air stream. |

| Oil Removal |

| Specialized filters, often made with activated carbon or similar materials, adsorb oil vapor and mist, preventing it from reaching downstream applications. |

| Pressure Regulation |

| Some filters also include pressure regulators to maintain the desired air pressure in the system. |

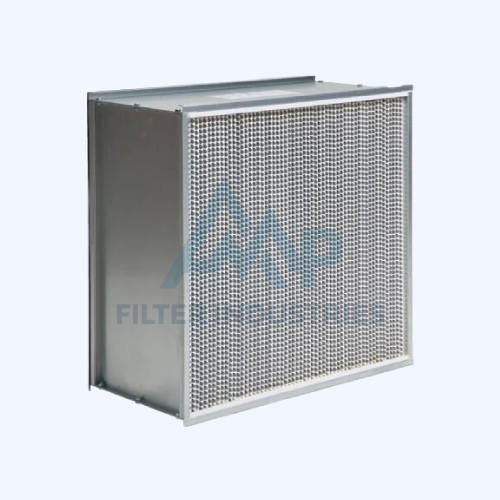

Compressed Air Filter

Compressed Air Filter

Compressed air filters are essential components in compressed air systems, designed to remove contaminants such as particulates, oil, and moisture from the compressed air. These filters ensure that the air delivered to tools, equipment, and processes is clean and free from impurities, which can cause damage or reduce efficiency. Here’s an overview of compressed air filters, their types, functions, and applications:

How Compressed Air Filters Work

Compressed air filters operate by passing the air through filter media that traps contaminants. The process typically involves:

- Compressed Air Filter

- Types of Compressed Air Filters

- Features and Benefits

- Applications

- Design Considerations

| Particulate Filters |

| Purpose: Remove solid particles from the air. |

| Applications: Used in general-purpose air filtration to protect equipment and maintain air quality. |

| Coalescing Filters |

| Purpose: Remove oil and water aerosols from the air. |

| Applications: Essential in industries where air purity is critical, such as food and beverage processing, pharmaceuticals, and electronics manufacturing. |

| Activated Carbon Filters |

| Purpose: Adsorb oil vapors and odors. |

| Applications: Used in applications requiring high air quality and odor removal, such as in painting and coating operations. |

| Refrigerated Air Dryers |

| Purpose: Cool the air to condense and remove moisture. |

| Applications: Common in systems where dry air is necessary to prevent corrosion and ensure efficient operation. |

| Desiccant Dryers |

| Purpose: Use desiccant materials to absorb moisture from the air. |

| Applications: Suitable for environments requiring extremely dry air, such as in laboratories and medical facilities. |

| Improved Air Quality |

| Ensures that compressed air is free from contaminants, protecting equipment and enhancing product quality. |

| Improved Air Quality |

| Reduces wear and tear on tools and machinery by preventing abrasive particles and corrosive moisture from entering the system. |

| Energy Efficiency |

| Proper filtration reduces energy consumption by ensuring optimal air flow and pressure. |

| Compliance with Standards |

| Meets industry standards and regulations for air quality, such as ISO 8573-1. |

| Manufacturing |

| Used in assembly lines, CNC machines, and robotic systems to ensure clean air for operation. |

| Food and Beverage |

| Ensures that air used in packaging, processing, and bottling is free from contaminants. |

| • Pharmaceuticals |

| Maintains sterile conditions and prevents contamination in drug manufacturing processes. |

| Automotive |

| Used in paint booths and assembly lines to ensure high-quality finishes and efficient operation. |

| Electronics |

| Protects sensitive equipment and ensures clean air for processes like circuit board manufacturing. |

| Design Considerations |

| When selecting a compressed air filter, consider the following: |

| Air Quality Requirements |

| Determine the level of purity needed for the specific application. |

| Flow Rate and Pressure |

| Ensure the filter can handle the required flow rate and pressure without causing excessive pressure drop. |

| Environmental Conditions |

| Consider the operating temperature, humidity, and potential exposure to chemicals. |

| Maintenance |

| Choose filters that are easy to maintain and replace to minimize downtime. Conclusion |

| Design Considerations |

| Compressed air filters are vital for maintaining the quality and efficiency of compressed air systems across various industries. By selecting the right type of filter for specific applications, businesses can ensure reliable operation, reduce maintenance costs, and comply with industry standards for air purity. |