| Construction and Materials |

| Liquid filter bags are constructed from a variety of materials, each chosen for its specific filtration properties and compatibility with different substances. Common materials include |

| Polypropylene |

| Offers excellent chemical resistance and is suitable for a wide range of applications. It is also an FDA-approved material for food and beverage use. |

| Polyester |

| Known for its strength and durability, polyester is often used in demanding environments. |

| Nylon Monofilament |

| Provides high strength and resistance to abrasion, suitable for applications requiring precision filtration. |

| Nomex Felt |

| Offers high-temperature resistance, making it ideal for use in hot liquid filtration processes. |

| Nylon & Polyester Multifilament |

| Provides a combination of strength and flexibility for various industrial applications. |

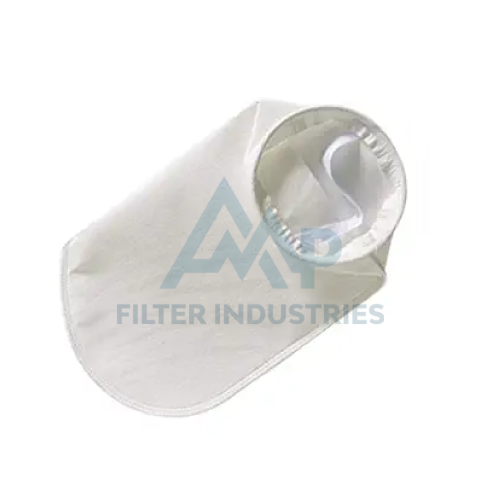

Filter Bags Liquid

Filter Bags Liquid

Liquid filter bags are an essential component in industrial filtration systems, designed to separate solids from liquids in various applications. They are used across multiple industries to ensure that liquids are free from particulates, contaminants, and impurities, providing a clean and efficient end product. Here’s an in-depth look at liquid filter bags, their construction, features, and applications:

- Construction and Materials

- Features

- Types of Filter Media

- Technical Specifications

- Applications

- Conclusion

| High Dirt Holding Capacity: |

| Liquid filter bags can capture a significant amount of solids, reducing the need for frequent changes and maintenance. |

| Wide Chemical Compatibility |

| The materials used in filter bags are compatible with a broad range of chemicals, making them versatile for different industrial uses. |

| Silicone-Free Construction |

| Prevents contamination in applications where silicone could be detrimental, such as in automotive and paint processes. |

| Low Pressure Drop |

| Engineered to maintain efficient flow rates with minimal resistance, ensuring system performance is not compromised. |

| Easy Installation and Maintenance |

| Designed for quick replacement, reducing downtime and operational costs. |

| Polypropylene Filter Bags |

| Widely used for their chemical resistance and affordability. |

| Absolute Filter Bags |

| Provide precise filtration, capturing particles as small as one micron with high efficiency. |

| Carbon Bags |

| Used to adsorb odors and remove organic contaminants from liquids. |

| Water Absorbent Bags |

| Specifically designed to remove water from hydrocarbons and other fluids. |

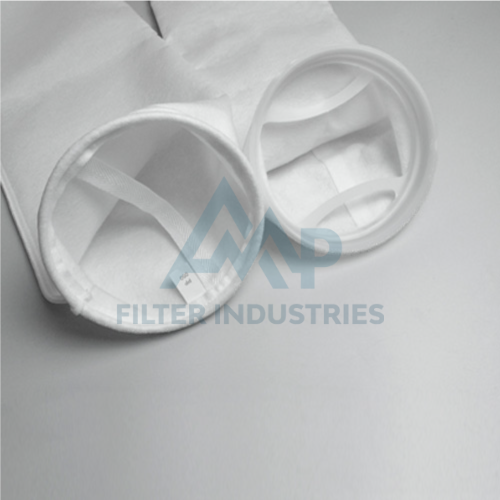

| Sizes |

| Liquid filter bags come in various standard sizes to fit different housing units. Common sizes include: |

| 4" x 10" Long |

| 4" x 17" Long |

| 4" x 20" Long |

| 7" x 17" Long |

| 7" x 32" Long |

| 6" x 20" Long |

| Filtration Ratings |

| Available in a range of micron ratings to meet different filtration needs, including 1, 2, 5, 10, 25, 50, 100, 150, and 200 microns. |

| Construction Options |

| Bags can be sewn or welded, with sealing options including steel O-rings or molded plastic snap seal rings for secure installation. |

| Applications |

| Liquid filter bags are used in a wide variety of industries due to their versatility and effectiveness: |

| Paints, Lacquers, and Varnish: |

| Ensures smooth and consistent application by removing impurities that could affect finish quality. |

| Inks and Resins |

| Filters out particulates to maintain consistency and quality in production processes. |

| Adhesives and Oils |

| Removes contaminants that can affect adhesive strength and oil purity. |

| Bitumen and Fats |

| Provides reliable filtration for materials with high viscosity. |

| Plasticizers and Pharmaceuticals |

| Ensures high purity and quality in sensitive applications. |

| Food Ingredients and Vegetable Oils |

| Meets food-grade standards for safety and quality. |

| Cooling and Heating Water |

| Protects systems from fouling by removing particulates and debris. |

| Cutting Fluids and Oils |

| Extends fluid life by filtering out metal particles and other impurities. |

| High Viscosity Fluids |

| Suitable for challenging applications such as honey and wax filtration. |

| Conclusion |

| Liquid filter bags are a critical component in maintaining the efficiency and effectiveness of industrial filtration systems. Their ability to handle high dirt loads, provide wide chemical compatibility, and offer easy maintenance makes them an invaluable asset across a wide range of applications. By selecting the appropriate filter bag material and design, industries can ensure optimal performance and compliance |