| Purpose |

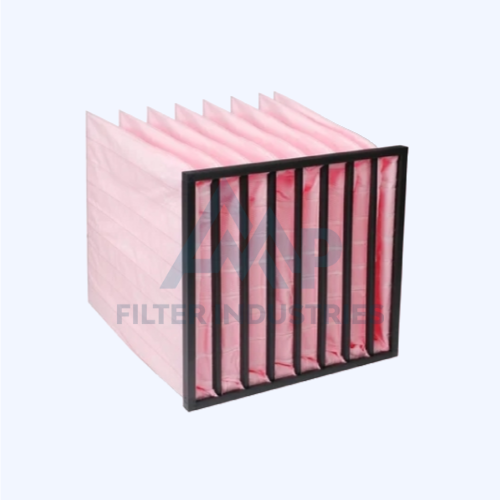

| Filter cages provide structural support to filter bags, preventing them from collapsing during operation. |

| They are essential in ensuring the bag's surface area is maximized for effective filtration. |

| Materials |

| Typically made from materials like carbon steel, stainless steel, or galvanized steel. |

| The material choice depends on the operating conditions, including temperature, humidity, and the nature of the particles being filtered. |

| Design |

| Consists of vertical wires and horizontal rings to form a cylindrical shape. |

| The design can vary to optimize airflow and minimize wear and tear on the filter bags. |

| Considerations |

| Cages must be designed to fit precisely within the filter bag and housing. |

| They should be corrosion-resistant to prolong their lifespan and maintain efficient operation. |

Filter Cage & Ventury

Filter Cage & Ventury

Filter cages and venturis are components used in industrial baghouse filtration systems. Here’s an overview of each

| Purpose |

| A venturi is used in baghouse systems to enhance the cleaning process of the filter bags. |

| It increases the velocity of air or cleaning gas injected into the bags, improving the removal of accumulated dust. |

| Design |

| Typically a short tube with a constricted throat (narrowest part) and an expanding section downstream. |

| This shape accelerates the cleaning air and creates a venturi effect, aiding in the thorough cleaning of the filter media. |

| Materials |

| Often made from metals such as cast iron, aluminum, or stainless steel, depending on the environment and type of dust being handled. |

| Functionality |

| By creating a high-velocity air pulse, the venturi helps dislodge dust cakes from the filter bag's surface. |

| It is crucial for maintaining the efficiency and longevity of the filtration system by reducing pressure drop and ensuring proper airflow. |

| Both filter cages and venturis are widely used in industries where dust collection is critical, such as: |

| Cement production |

| Power plants |

| Chemical manufacturing |

| Metalworking |

| Pharmaceuticals |

| Applications |

| In these applications, the combination of filter cages and venturis helps maintain efficient operation, reduce maintenance costs, and comply with environmental regulations by controlling particulate emissions. |

| Regular Inspection |

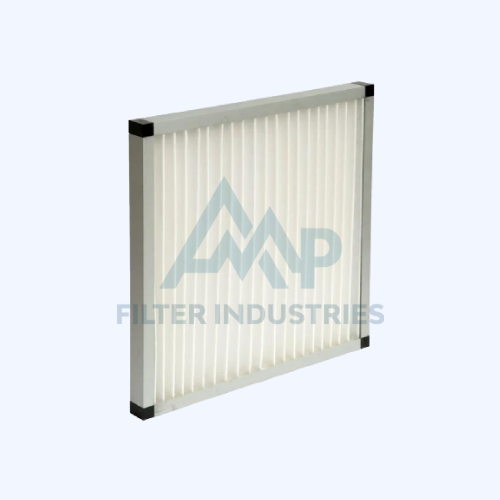

| Periodically check the strainer for accumulated debris and inspect the filter element for damage. |

| Cleaning |

| Remove the strainer cap and clean the filter element as needed to maintain optimal performance. |

| Replacement |

| Replace the filter element or the entire strainer if it becomes damaged or clogged beyond repair. |

| Maintenance |

| Y strainers are an essential component in many systems, providing effective filtration and protection for various applications. |