| Material Composition |

| Filter Media: Made from continuous filament glass fibers. |

| Core Material: Typically made from materials like stainless steel, polypropylene, or other metals and plastics, depending on the application requirements. |

| Filtration Capabilities |

| Micron Ratings: Generally available in a wide range of micron ratings, from 1 to 200 microns, allowing for customized filtration levels. |

| High Dirt Holding Capacity: The depth filtration design ensures a high dirt holding capacity, which extends the filter life. |

| Temperature Resistance: Glass fibers can withstand higher temperatures compared to many other filter materials, typically up to around 400°F (204°C). |

| Performance |

| Pressure Drop: Low initial pressure drop due to the open, porous structure, but it increases as particulates are captured. |

| Chemical Compatibility: Excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. |

| Dimensions |

| Length and Diameter: Available in various standard lengths (e.g., 10", 20", 30", 40") and diameters, often customizable to meet specific application needs. |

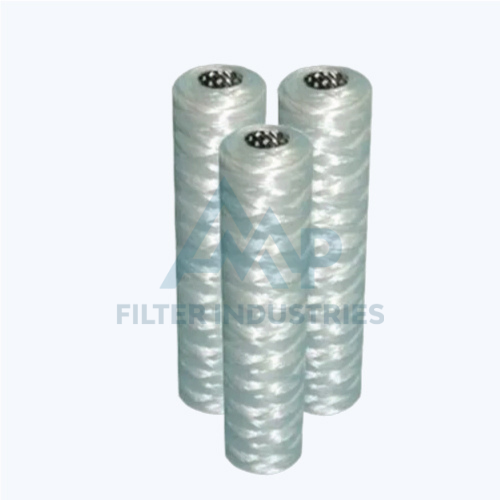

Glass Fiber Wound Cartridge

Glass Fiber Wound Cartridge

Glass fiber wound cartridges are a type of filter cartridge known for their ability to remove particulates from liquids and gases. These filters are constructed by winding continuous glass fibers around a central core, creating a dense and durable filtering medium. Here’s a detailed look at their features, specifications, and applications:

| Industrial Processes |

| Chemical Processing: Suitable for filtering aggressive chemicals and solvents. |

| Petroleum and Oil Refining: Used to remove particulates from oil and other hydrocarbons. |

| Power Generation: Employed in water treatment and filtration of fuel and lubricants. |

| Design |

| Typically a short tube with a constricted throat (narrowest part) and an expanding section downstream |

| This shape accelerates the cleaning air and creates a venturi effect, aiding in the thorough cleaning of the filter media. |

| Water Treatment |

| Municipal and Industrial Water: Effective in pre-filtration stages to protect more sensitive downstream processes. |

| Food and Beverage |

| Filtration of Liquids: Used in processes where high purity and the absence of organic media are required. |

| Pharmaceutical and Biotech |

| Process Fluids: Utilized in the filtration of aggressive fluids that require a non-reactive filter medium. |

| Advantages |

| Durability: Glass fiber wound cartridges are robust and can handle harsh operating conditions. |

| Versatility: Suitable for a wide range of applications due to their chemical and thermal stability. |

| Cost-Effectiveness: Long service life and high dirt holding capacity can lead to reduced maintenance costs. |

| Considerations |

| Handling: Glass fibers can be fragile, and care must be taken during installation and handling to prevent damage. |

| Disposal: Proper disposal is necessary as glass fibers may pose environmental and health risks if not managed correctly. |

| These characteristics make glass fiber wound cartridges a popular choice for industries requiring high-performance filtration solutions in challenging environments. |