| Contaminant Removal |

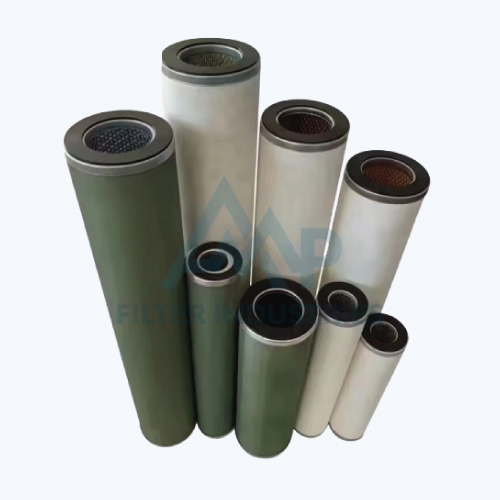

| Filtration: Designed to remove particulates such as dirt, metal shavings, and other debris from hydraulic oil to prevent wear and tear on system components. |

| Efficiency: Effective at capturing contaminants of various sizes to ensure clean hydraulic fluid |

| Filtration Media |

| Materials: Typically made from materials like cellulose, synthetic fibers, or a combination of both, and sometimes incorporate pleated designs for increased surface area. |

| Micron Ratings: Available in different micron ratings to match the specific filtration needs of the hydraulic system. |

| Construction |

| Housings: Usually made from metal or reinforced plastic to withstand high pressures and harsh operating conditions. |

| Seals and Gaskets: Equipped with seals and gaskets to ensure leak-proof operation. |

| Bypass Valve |

| Function: Many hydraulic filters include a bypass valve that allows fluid to flow through the filter even if it becomes clogged, preventing system damage and ensuring continuous operation. |

| Pressure Differential Indicator |

| Feature: Some filters have an indicator to signal when the filter is becoming clogged and needs to be replaced. |

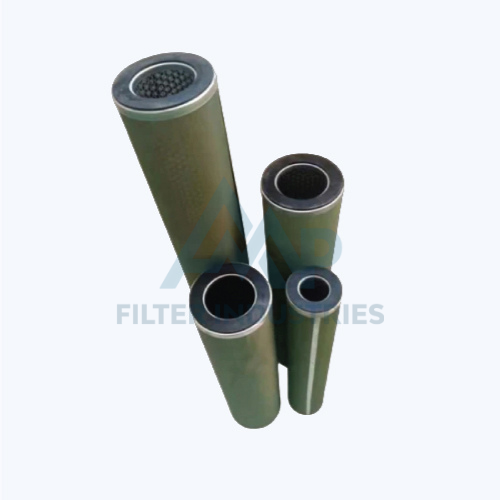

Hydraulic Oil Filter

Hydraulic Oil Filter

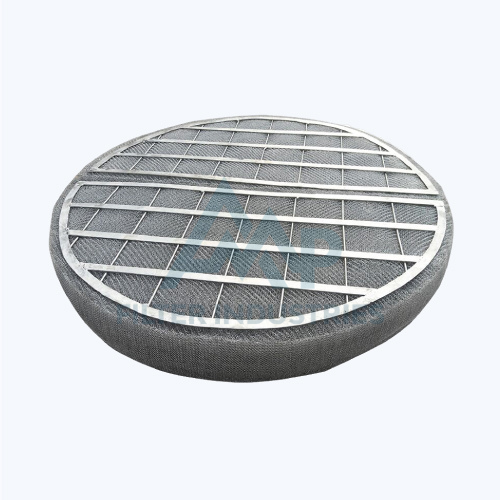

A demister pad is an essential component used in various industrial processes to remove liquid droplets from gas streams. These devices are crucial for ensuring the purity of gases and preventing liquid carryover, which can cause operational issues or contamination in subsequent processes. Here’s a detailed look at demister pads, including their function, types, and applications:

What is a Demister Pad?

A demister pad, also known as a mist eliminator, is a porous pad typically made of knitted or woven wire mesh or other materials like plastic or fiberglass. Its primary function is to separate liquid droplets from gas streams, ensuring that the exiting gas is free from entrained liquids.

| Inline Filters |

| Design: Positioned directly in the hydraulic line, these filters are typically compact and easy to install. |

| Application: Commonly used for general filtration needs. |

| Return Line Filters |

| Design: Installed in the return line, where the fluid returns from the system to the reservoir. |

| Function: Helps remove contaminants before the fluid re-enters the reservoir. |

| Pressure Line Filters |

| Design: Located in the high-pressure line before the hydraulic fluid reaches the components. |

| Function: Protects sensitive components from contaminants. |

| Suction Filters |

| Design: Placed at the inlet of the hydraulic pump, where the fluid is drawn from the reservoir. |

| Function: Prevents large particles from entering the pump. |

| High-Pressure Filters |

| Design: Built to withstand high pressures and are often used in systems with intense operating conditions. |

| Function: Ensures reliable filtration under high pressure. |

| Industrial Machinery |

| Purpose: Keeps hydraulic systems in machinery such as presses, lathes, and CNC machines operating smoothly and efficiently. |

| Construction Equipment |

| Purpose: Used in excavators, bulldozers, and other heavy equipment to protect hydraulic systems from contaminants. |

| Automotive |

| Purpose: Found in vehicles with hydraulic systems, such as power steering and automatic transmission systems. |

| Agricultural Equipment |

| Purpose: Filters are used in tractors, combines, and other agricultural machinery to maintain hydraulic system performance. |

| Aerospace |

| Purpose: Ensures the reliability and safety of hydraulic systems in aircraft and spacecraft. |

| Marine |

| Purpose: Used in ships and submarines to maintain hydraulic systems that control various onboard operations. |

| Regular Inspection |

| Monitor filter performance and check for clogging or contamination. |

| Replacement |

| Replace filters according to manufacturer recommendations or when the differential pressure indicator signals a need for change. |

| System Check |

| Ensure the hydraulic system is checked for leaks or damage when replacing filters. |

| Maintenance and Replacement |

| Hydraulic oil filters are vital for the longevity and performance of hydraulic systems. Proper selection, installation, and maintenance of these filters help ensure efficient operation and prevent costly damage to hydraulic components. |