| Construction and Media |

| Filter Media: Typically made from a combination of filtration materials such as pleated polypropylene or polyester, combined with an oil-adsorbing layer like polypropylene microfiber or activated carbon. |

| Adsorbent Core: May include a specialized core material for enhanced oil absorption and retention. |

| Filtration and Adsorption |

| Oil Adsorption: Designed to capture and adsorb free, non-emulsified oil from the fluid stream. This is particularly important for applications where oil contamination is a concern. |

| Micron Ratings: Available in various micron ratings (e.g., 1, 5, 10, 25, 50, 75, 100 microns) to handle different particle sizes and filtration requirements. |

| Extended Service Life |

| Durability: The larger size and high dirt-holding capacity mean fewer cartridge changeouts, leading to lower operational costs and reduced downtime. |

| Performance Characteristics |

| Flow Rates: Designed for specific flow rates to optimize oil removal and ensure efficient performance. Flow rates can vary based on cartridge size and application. |

| Capacity: Features increased surface area and adsorbent capacity to enhance oil removal efficiency and extend service life. |

| Design and Build |

| Construction: Cartridges are built to withstand the pressures and conditions of various systems, with robust materials and construction methods. |

| End Caps and Seals: Typically include durable end caps and seals to ensure a secure fit and prevent leaks. |

| Applications |

| Versatility: Suitable for a wide range of applications, including water treatment, automotive processes, industrial machinery, and more. |

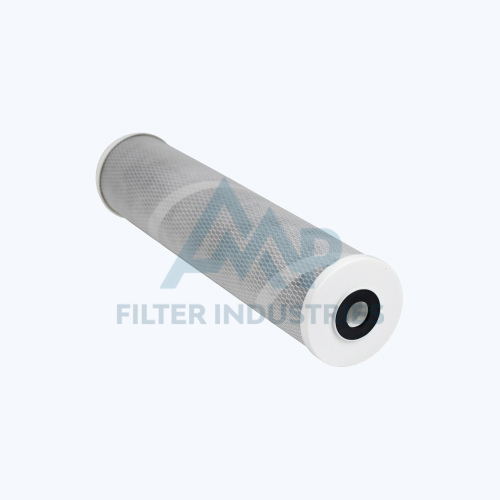

Oil Adsorbing Filter Cartridge

Oil Adsorbing Filter Cartridge

Oil-adsorbing filter cartridges are designed to efficiently remove free, non-emulsified oil from liquids in various industrial and commercial applications. These cartridges combine traditional filtration methods with advanced oil-adsorbing materials to improve the quality of fluids by eliminating oil contaminants. Here’s a detailed overview of oil-adsorbing filter cartridges:

- Key Features

- Types of Oil-Adsorbing Filter Cartridges

- Applications

- Maintenance and Replacement

- Summary

| Pleated Cartridges |

| Design: Feature pleated filtration media that increases surface area and dirt-holding capacity. |

| Application: Used in general oil removal and filtration applications. |

| Activated Carbon Cartridges |

| Design: Incorporate activated carbon as the primary adsorbent material for high-efficiency oil removal. |

| Application: Ideal for applications requiring the removal of trace amounts of oil and other contaminants. |

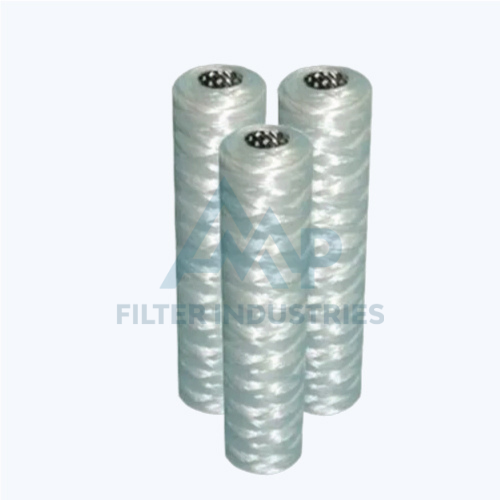

| Microfiber Core Cartridges |

| Design: Feature a core of specialized microfiber material for enhanced oil adsorption. |

| Application: Provides superior oil removal and is used in applications where high oil contamination levels are present. |

| Oil-Water Separator Cartridges |

| Design: Designed specifically for separating oil from water using a combination of filtration and adsorption. |

| Application: Used in wastewater treatment and oil-water separation processes. |

| Water Treatment |

| Use: Removes oil from process water, wastewater, and other liquid streams to meet environmental and operational standards. |

| Automotive |

| Use: Cleans fluids used in automotive processes, such as cooling systems and paint booths, to prevent oil contamination. |

| Industrial Processes |

| Use: Ensures clean and contaminant-free fluids in various industrial applications, including hydraulic systems and machinery |

| Food and Beverage |

| Use: Maintains the cleanliness of fluids used in food and beverage production processes. |

| Pharmaceuticals |

| Use: Ensures the purity of fluids used in pharmaceutical manufacturing and processing. |

| Maintenance and Replacement |

| Regular Monitoring: Check the performance of filter cartridges regularly to ensure they are functioning correctly and efficiently. |

| Replacement: Replace cartridges based on the manufacturer’s recommendations or when they become clogged or saturated with oil. |

| System Maintenance: Perform routine maintenance on the filtration system to ensure optimal performance and extend the life of the cartridges. |

| Summary |

| Oil-adsorbing filter cartridges are designed to effectively remove free, non-emulsified oil from liquids, providing enhanced filtration and adsorption capabilities. They come in various designs and configurations to suit different applications and flow rates, making them suitable for use in industries such as water treatment, automotive, industrial processes, and pharmaceuticals. By maintaining clean and contaminant-free fluids, these cartridges help improve operational efficiency, protect equipment, and meet industry standards. |