| Lower Maintenance Costs |

| Extended Filter Life: The increased surface area and higher dust retention capacity of pleated filters reduce the frequency of maintenance and replacement, leading to lower overall maintenance costs. |

| Efficiencies Up to 99.97% |

| High Efficiency: Pleated filters can achieve very high efficiency in capturing airborne particulates, including very fine dust particles, resulting in cleaner exhaust air. |

| Higher Air Flow Per Filter Unit |

| Improved Airflow: The pleated design allows for greater airflow through the filter media, enhancing the efficiency of the dust collection system and reducing energy consumption. |

| Less Frequent Change-Outs |

| Longer Service Life: Due to their high dust-holding capacity and efficient filtration, pleated filters generally require fewer replacements compared to traditional bag filters. |

| Better Resistance to Inlet Abrasion |

| Durability: The pleated design helps the filter withstand abrasion caused by incoming dust particles, extending the filter’s lifespan and maintaining performance. |

| Up to a 5-Fold Increase in Surface Filtration |

| Increased Filtration Area: The pleated structure provides up to five times more surface area compared to traditional bag filters, enhancing dust collection efficiency. |

| Washable Exterior |

| Easy Maintenance: Some pleated filters have washable exteriors, allowing for easier cleaning and reuse, which further reduces maintenance costs. |

| Minimizes Compressed Air Usage |

| Reduced Operational Costs: The enhanced dust holding capacity and lower air-to-cloth ratios help in minimizing the amount of compressed air needed for pulse cleaning, reducing operational costs. |

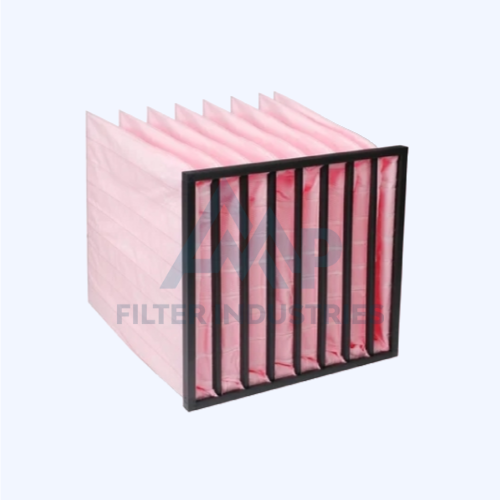

Pleated Dust Collection Bag

Pleated Dust Collection Bag

Pleated filters offer several advantages over traditional bag filters, making them an increasingly popular choice in dust collection systems. Here’s a detailed overview of the advantages, construction, and applications of pleated filters:

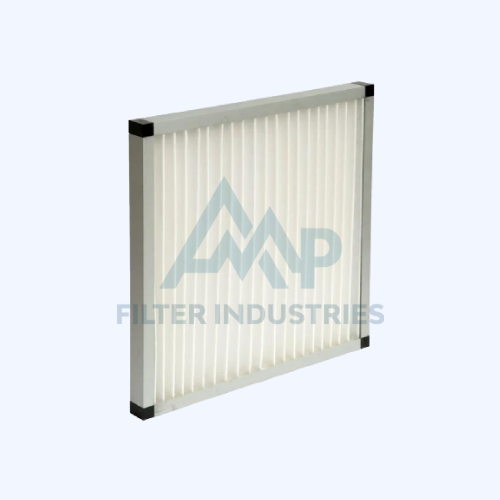

| Filter Media |

| Pleated Spun Bonded Polyester: The primary filter media used is spun-bonded polyester, which is pleated to increase surface area and filtration efficiency. |

| Support Cage |

| Materials: Made from galvanized steel, stainless steel, or polypropylene to provide structural support and maintain the pleated shape. |

| End Caps |

| Materials: Encapsulated with EPDM, natural rubber, polyurethane, or metal, designed to ensure a secure fit and prevent leaks. |

| Joint Sealing |

| Ultrasonic Fusion: Longitudinal joints are ultrasonically fused for leak-proof performance and stability. |

| Mounting and Sealing |

| Mounting Options: Designed to fit various cell plates for both top and bottom load dust collectors |

| Sealing: Metal caps are supported with soft sponge rubber or snap band cuffs to ensure a positive seal. |

| Pharmaceuticals |

| Use: For capturing fine dust and particles in pharmaceutical manufacturing processes. |

| Steel & Power |

| Use: In steel production and power plants to manage dust and particulate emissions. |

| Powder Coating |

| Use: To capture overspray and powder particles in coating operations. |

| Shot Blasting |

| Use: For dust collection in shot blasting processes. |

| Cement |

| Use: To manage dust generated during cement production. |

| Chemicals |

| Use: In chemical processing to control dust and ensure clean air. |

| Metals & Minerals |

| Use: For dust collection in metal and mineral processing. |

| Paints & Pigments |

| Use: To capture dust and particulates in paint and pigment manufacturing. |

| Pneumatic Conveying |

| Use: In systems that transport materials pneumatically to manage dust emissions. |

| Spray Dryer |

| Use: For dust collection in spray drying processes. |

| Summary |

| Pleated dust collection bags offer significant advantages over traditional bag filters, including increased filtration surface area, higher efficiency, lower maintenance costs, and better resistance to abrasion. Their construction, including pleated polyester media, support cages, and secure end caps, ensures reliable performance and durability. These filters are suitable for a wide range of industrial applications, including pharmaceuticals, steel production, powder coating, and more. |