| Description |

| Material: Polypropylene microfiber, constructed through hot-melt entanglement. |

| Structure: Three-dimensional microporous structure with pleated design. |

| Construction: Hot-melt welding technology used for the cage, core, and end caps, ensuring no adhesives are used. This design promotes a clean environment with no pollution or leakage. |

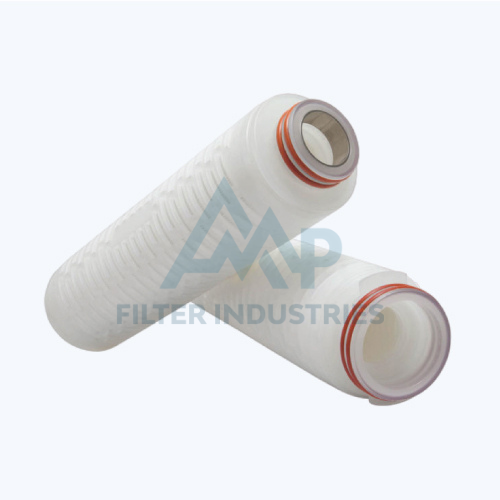

Polypropylene Pleated Cartridge

Polypropylene Pleated Cartridge

Polypropylene Pleated Cartridge

The polypropylene pleated filter cartridge from AMP FILTER INDUSTRIES is designed for high-performance filtration in various industries. Here’s an overview of its key aspects:

| Material |

| Pure polypropylene structure, providing broad chemical compatibility. |

| Filtration |

| Micron Ratings: Available from 0.1 to 50μm, with standard options including 0.1, 0.2, 0.45, 1, 5, 10, 20μm. |

| Filtration Area: High surface area, more than 0.5 m² per 10″ filter. |

| Density: Gradient density micron fiber media. |

| Performance |

| Flow Rate: High flow rate with low differential pressure |

| Service Life: Long service life due to large pollutant retention capacity. |

| Construction |

| Thermally Welded: No adhesive, robust outer cage, biologically safe |

| FDA Approved: Meets FDA standards. |

| No Fiber Migration: Ensures reliability and consistency in filtration. |

| Technical Specifications |

| Sizes: 5 inch, 10 inch, 20 inch, 30 inch, 40 inch. |

| Micron Ratings: 0.1μm to 50μm. |

| Outer Diameter: 69 mm |

| Inner Diameter: 28 mm |

| Applications |

| Food and Beverage Industry: Prefiltration for bottled water, beverages, fruit juices, alcohol. |

| Biomedical Industry: Prefiltration of preparations and biological products, compressed air and gas prefiltration. |

| Microelectronics Industry: Pure water filtration for semiconductor and panel manufacturers, prefiltration for reverse osmosis water. |

| Chemical Industry: Prefiltration of chemical raw materials, including organic solvents and general acids and bases. |

| Petroleum Industry: Prefiltration for oilfield downhole water injection. |

| This cartridge offers broad chemical compatibility, high efficiency, and a variety of sizes and micron ratings, making it suitable for a range of industrial filtration needs. |

| Double Open End (DOE) |

| Standard configuration with open ends for various housing designs. |

| Code 7S |

| 226 O-Ring Design / Bayonet |

| Code 7F |

| 226 O-Ring Design / Flat |

| Code 3S |

| 222 O-Ring Design / Bayonet |

| Code 3F |

| 222 O-Ring Design / Flat |