| Description |

| Construction: Made from acrylic fibers and phenolic resins, with adhesives, curing agents, and stabilizers applied through high-temperature sintering. |

| Structure: Gradually tightening hard structure, allowing the cartridges to handle extreme viscosity and temperatures without deformation or collapse. Features grooves on the surface to expand the effective filtration area. |

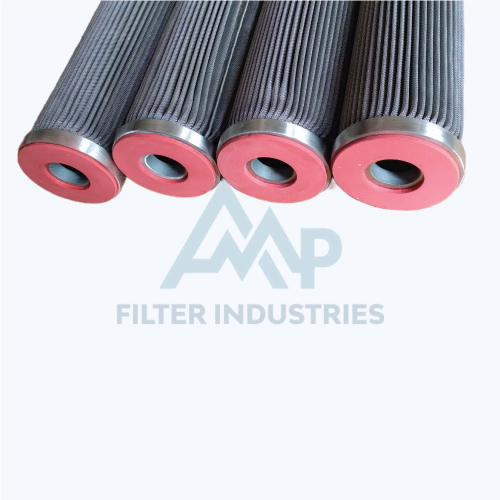

Resin-Bonded Filter Cartridge

Resin-Bonded Filter Cartridge

Resin-Bonded Filter Cartridge

Resin-bonded filter cartridges are high-performance filtration devices designed for demanding applications, particularly in chemical and industrial processes. Here’s an overview of their features, specifications, and applications:

| Key Features |

| No Fiber Shedding: Ensures cleanliness and high filtration efficiency without releasing fibers. |

| High Filtration Rating: Capable of achieving ultra-high filtration efficiency of 99.9%. |

| Chemical Compatibility: Resistant to solvents, corrosion, and a wide range of chemicals. |

| Temperature and Pressure Resistance: Withstands high temperatures and pressures. |

| Effective Filtration Area: Grooved surface structure increases the filtration area and capacity. |

| Flow Rate and Resistance: Provides large flow rates with low resistance, effectively filtering particulate impurities. |

| Technical Specifications |

| Filter Media: Acrylic Fiber / Phenolic Resin. |

| Lengths Available |

| 5" (127 mm) |

| 9.8" (248 mm) |

| 10" (254 mm) |

| 20" (508 mm) |

| 30" (762 mm) |

| 40" (1016 mm) |

| Inside Diameter: 28 mm, 30 mm. |

| Outside Diameter: 2.55" (65 mm). |

| Filtration Ratings |

| 1 μm |

| 5 μm |

| 10 μm |

| 25 μm |

| 50 μm |

| 75 μm |

| 100 μm |

| 125 μm |

| 150 μm |

| 200 μm |

| End Cap: Double Open End (DOE). |

| Recommended Flow Rates (for 10" Cartridges): |

| Industry Impact |

| Industry Impact |

| 5 μm: 22 L/min. |

| 10 μm: 30 L/min. |

| 50 μm: 40 L/min. |

| Performance Data |

| Maximum Operating Temperature: 125°C. |

| Max. Working Pressure: 25 bar. |

| Max. Differential Pressure: 4.8 bar. |

| Applicable Acidity & Alkalinity: pH 4 - 9. |

| Liquid Flow Direction: Outside to inside. |

| Recommended Change-Out Differential Pressure: 2.5 bar. |

| Applications |

| Paints & Inks: Filtration of paints, dyes, and inks in the manufacturing process. |

| Organic Solvents: Effective for solvents used in various chemical processes. |

| Machine Coolants: Filters used in cooling systems of machinery. |

| Chemical Industry: Suitable for filtration of chemicals, including acids and bases. |

| Lacquers & Varnishes: Filtration in the production of coatings and finishes. |

| Coatings & Epoxies: Ensures purity in epoxy and coating formulations. |

| Sealants & Adhesives: Filters used in sealant and adhesive production. |

| Petrochemical Industry: Filtration of petrochemicals and related fluids. |

| Lubricating Oils & Hydraulic Fluids: Ensures clean lubricants and hydraulic fluids for machinery. |