| Powder Mixing |

| Materials: Elemental or alloy powders are mixed to create the desired composition for the filter cartridge. |

| Compaction: The mixture is compacted into the desired shape using a die. |

| Sintering |

| Heating: The compacted shapes are heated in a controlled atmosphere furnace. |

| Bonding: Particles bond together during heating, forming a porous structure. |

| Structure: The sintered material maintains its shape while allowing fluid, air, or gas to pass through. |

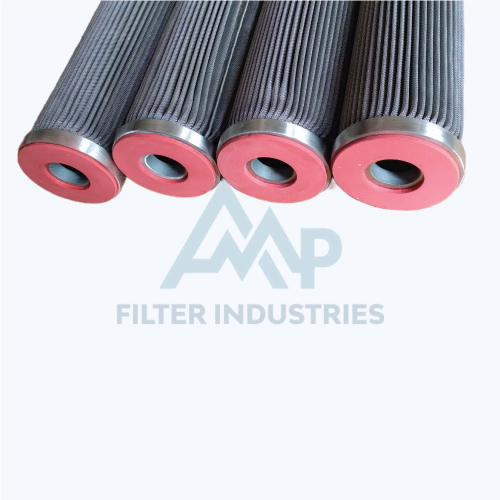

| Porous Structure |

| Filtration: The porous structure enables effective filtration while withstanding high differential pressures. |

| Robustness: Capable of handling particles above the specified micron rating. |

| Cleaning: Can be backwashed to remove deposited particles and maintain performance. |

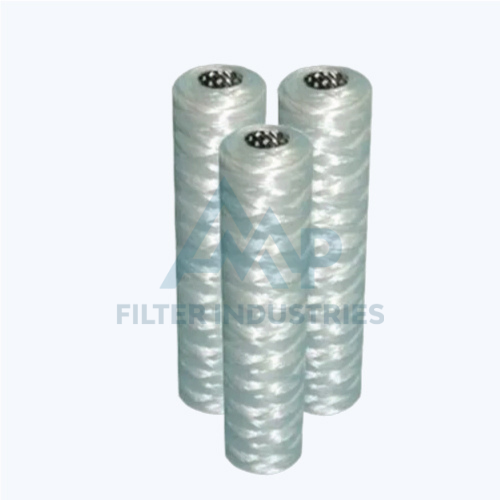

Sintered (Non – Metallic) Filter Cartridges

Sintered (Non – Metallic) Filter Cartridges

Sintered (Non-Metallic) Filter Cartridges

| Compressed Air Filtration |

| Compressed Air Filtration: Removes contaminants from compressed air systems to ensure clean air supply. |

| Gas Filtration |

| Filters gases in various industrial processes, including petrochemicals and electronics. |

| Fine Chemicals and Solvents |

| Used in chemical processes for filtration of fine chemicals, solvents, and process streams. |

| Magnetic Coating Dispersions |

| Filters used in coating lines and magnetic coating dispersions. |

| Petrochemicals |

| Applicable in water flooding, completion fluids, and amines within the petrochemical industry. |

| Cosmetics |

| Filters for alcohols, essential oils, and water lines in cosmetic manufacturing. |

| Water Treatment |

| Protects membranes and traps resins in water treatment systems. |

| Metal Finishing |

| Used in plating solutions, paint, resin products, and wash processes for metal finishing. |

| Electronics |

| Critical for electroplating, etching, and image development in electronics manufacturing. |

| Benefits |

| High Differential Pressure Tolerance: Can withstand very high differential pressures without structural failure. |

| Durability: Robust and durable, suitable for harsh environments and high-demand applications. |

| Effective Filtration: Provides efficient filtration with a porous structure that allows precise control of filtration. |

| Sintered non-metallic filter cartridges are ideal for applications requiring durable, high-performance filtration with the ability to handle demanding conditions. |