| Material Composition |

| Filter Media: Typically made from stainless steel (such as SS304, SS316) or other corrosion-resistant alloys. |

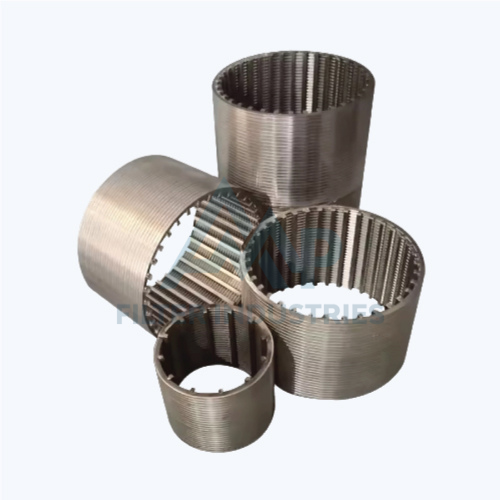

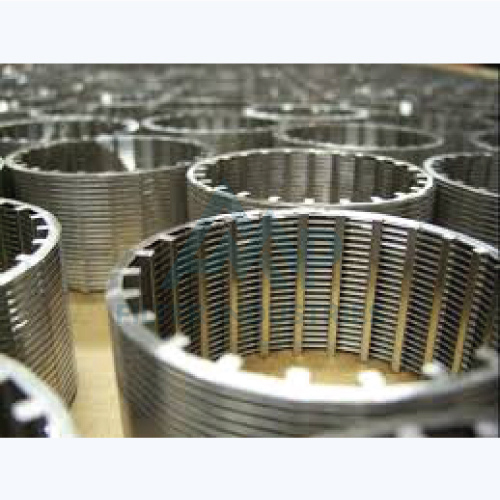

| Support Structure: Consists of crossbars or rods to provide structural integrity and support to the wedge wire. |

| Filtration Capabilities |

| Slot Openings: Precise slot openings ranging from 0.05 mm to 10 mm, providing accurate filtration and screening. |

| High Flow Rates: Designed to allow high flow rates while maintaining effective filtration, due to their open profile design. |

Wedge Wire Filter Element

Wedge Wire Filter Element

Wedge wire filter elements are robust and durable filtration solutions used across various industries for their strength and ability to handle high flow rates. These elements consist of V-shaped wire wrapped around a series of support rods, forming a precise and continuous slot opening. Here’s an in-depth look at their features, specifications, and applications:

| Backwashing Capability |

| Easily cleaned through backwashing, reducing downtime and maintenance costs. |

| Dimensions |

| Customizable Sizes: Available in various diameters and lengths to fit specific application needs. |

| Shape: Can be designed in cylindrical, flat, or curved shapes depending on the installation requirements. |

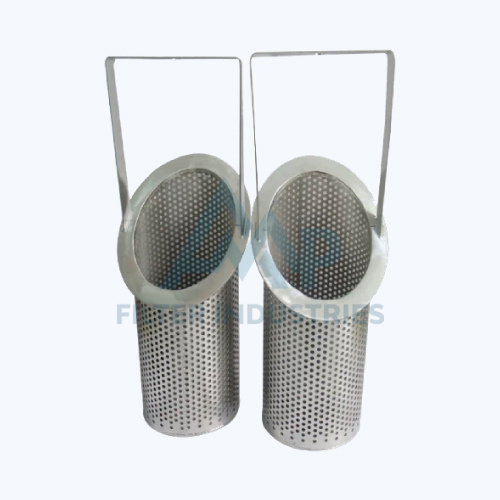

| Water Treatment |

| Intake Screening: Used in municipal and industrial water treatment for screening debris from water intakes. |

| Wastewater Management: Effective in separating solids from liquids in wastewater treatment plants. |

| Mining and Aggregate |

| Ore Processing: Employed in mineral and aggregate processing for dewatering and classifying. |

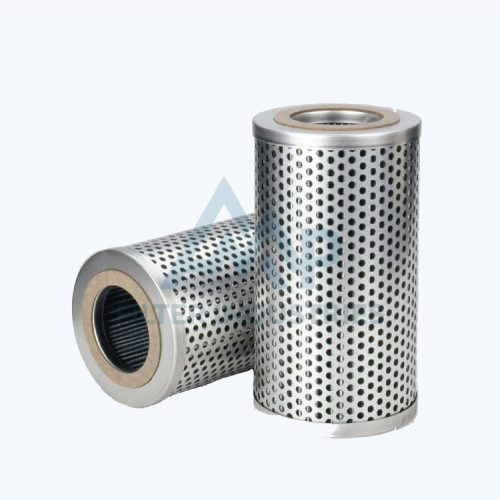

| Oil and Gas: |

| Sand Control: Utilized in oil wells to prevent sand from entering production equipment. |

| Refinery Applications: Used in the separation and filtration of hydrocarbons. |

| Food and Beverage |

| Filtration: Used in breweries and food processing for filtering liquids and separating solids. |

| Pulp and Paper |

| Pulp Processing: Used to separate fibers and contaminants from pulp slurries. |

| Durability and Longevity: |

| Made from stainless steel, wedge wire elements are highly resistant to corrosion and wear, offering a long service life. |

| Ease of Maintenance |

| The backwashing feature allows for quick cleaning without the need for disassembly. |

| High Precision |

| Accurate slot dimensions ensure consistent and reliable filtration performance. |

| Customizable |

| Can be tailored to specific applications with various slot sizes, shapes, and materials. |

| Considerations |

| Cost: Initial cost may be higher compared to some other filter types, but this is often offset by their durability and low maintenance requirements. |

| Installation: Requires proper handling and installation to ensure optimal performance and longevity. |

| Considerations |

| Wedge wire filter elements are an excellent choice for applications requiring reliable and durable filtration solutions, especially where high flow rates and mechanical strength are necessary. Their versatility and robustness make them suitable for challenging industrial environments. |